VIBROPRILLING TECHNOLOGY

Many fertilizer producers struggle to successfully operate on the market because of problems associated with the poor agricultural characteristics of their product. Vibroprilling is an innovative technology that allows achieving a very sharp prill size distribution, increase an average prill size along with increasing production on existing prilling plants. By improving a general quality of the product vibroprilling also addresses common problems such as caking susceptibility, necessity to sieve the product and last but not least the environmental impact of dust emission are the factors which result in increased production costs. Our technology allows adjusting the prill size (maintaining sharp prill size distribution) according to requirements and production conditions.

KCVT has developed vibroprilling technologies for different types of towers

- ODP Vibropriller designed for small diameter towers.

- WU Vibropriller designed for large diameter towers.

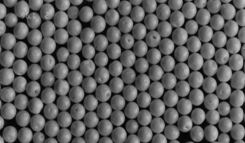

Both vibroprillers give a product of a very sharp prill size distribution with the amount of the desired fraction of up to 95% and its size of 1.4 – 3 mm.

Prills from prilling heads

Prills from Vibropriller

SIEVE ANALYSIS |

||||||

| PRILLING HEADS | VIBRO PRILLER | |||||

| Description | Units | Description | Units | |||

| Mesh 8, 2.36 mm | Wt.% | 1,1 | Mesh 8, 2.36 mm | Wt.% | 1,9 | |

| Mesh 10, 1.7 mm | Wt.% | 18,5 | Mesh 10, 1.7 mm | Wt.% | 94,0 | |

| Mesh 12, 1.4 mm | Wt.% | 24,9 | Mesh 12, 1.4 mm | Wt.% | 2,9 | |

| Mesh 14, 1.18 mm | Wt.% | 31,8 | Mesh 14, 1.18 mm | Wt.% | 0,8 | |

| Mesh 16, 1.0 mm | Wt.% | 16,9 | Mesh 16, 1.0 mm | Wt.% | 0,1 | |

| Mesh 20, 0.85 mm | Wt.% | 5 | Mesh 20, 0.85 mm | Wt.% | 0,1 | |

| Below 20 | Wt.% | 1,8 | Below 20 | Wt.% | 0,2 | |